Turnkey projects "Liepājas enerģija" Biomass Cogeneration Plant Liepaja , Latvia

One of the main objectives of developing the "Liepājas enerģija" biomass cogeneration plant was diversifying the types of fuel, thus increasing energy independence and ensuring a safe, steady and competitive heat supply to the city of Liepāja. Due to the new UPB Energy cogeneration plant, "Liepājas enerģija" was able to make the first crucial step towards diversifying the types of fuel, opting for woodchips as a renewable local resource. Using this renewable energy resource allows citizens to save on thermal energy costs and reduces the amount of harmful emissions, making the new cogeneration plant much more beneficial to the environment and people than other heat and energy supply solutions.

In one hour, the biomass cogeneration plant is able to produce 12 MW of thermal energy and 2.3 MW of electrical energy.

The produced thermal energy is used in the city’s centralised heating system. The thermal energy from woodchips is enough to supply 67% of "Liepājas enerģija" customers.

The electrical energy produced at the cogeneration plant is fed into the country’s electrical grid.

•12 MWththermalload

•2,3 MWeelectricalload

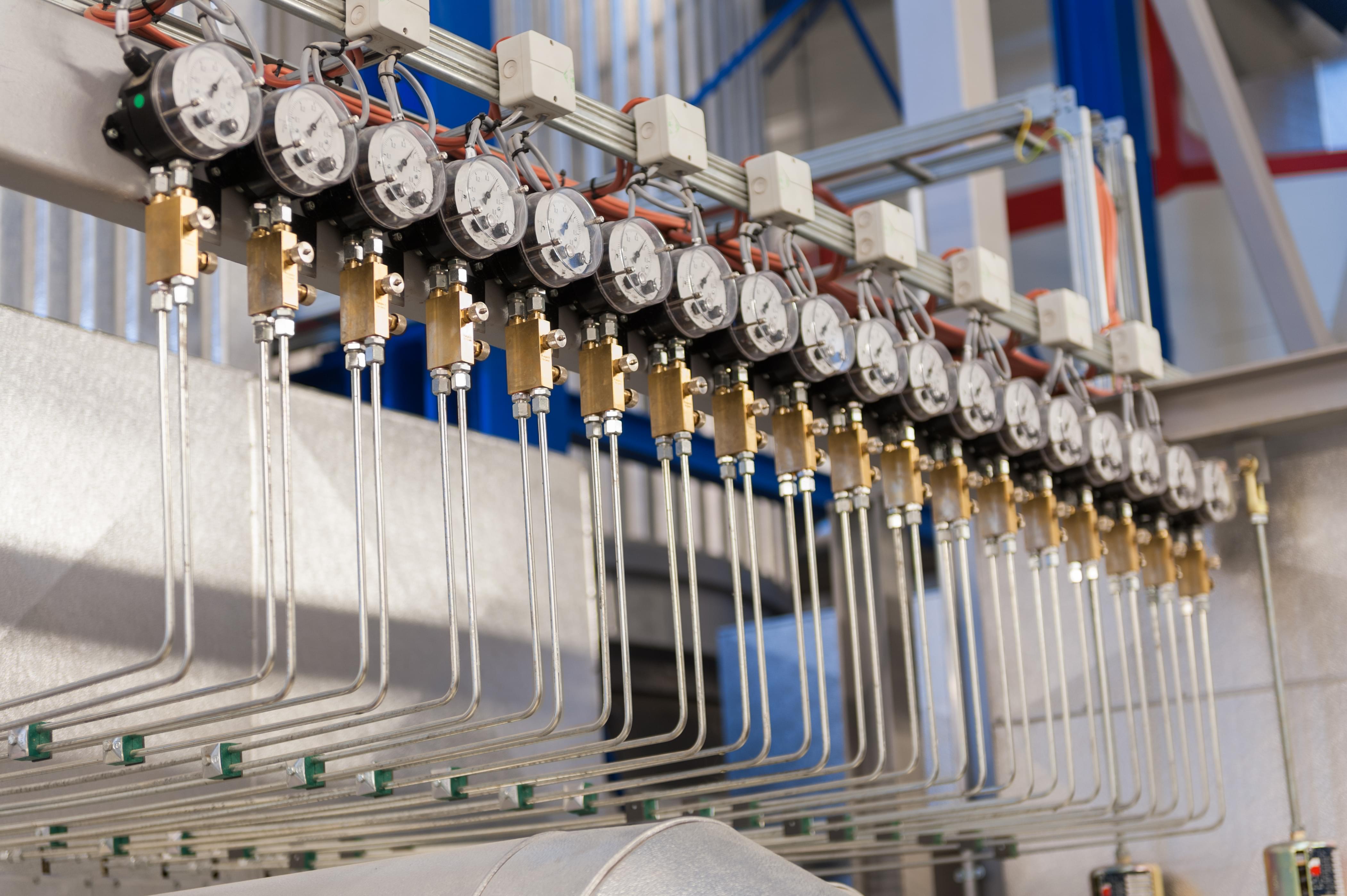

•Thermaloilboiler

•ORC turbine

•Fuel–Biomass(woodchips)

•Electrostaticprecipitator

•Fluegascondenser

UPB Energy built the cogeneration plant in cooperation with other companies of the UPB Group, taking care of the entire construction cycle: from designing the building to launching and fine-tuning the equipment and commissioning the object.

Keeping the entire construction cycle within the UPB Group allowed for efficient work organisation and use of resources.